What Is A Steeplejack? The Story of Peter Harknett

By Simon Smith

It’s odd, really. Peter Harknett is quite a local man, yet a renowned steeplejack in the counties of Sussex, Hampshire and Surrey. Still an active octogenarian, Peter could be found still assailing heights, far and wide until the 2020 lockdown.

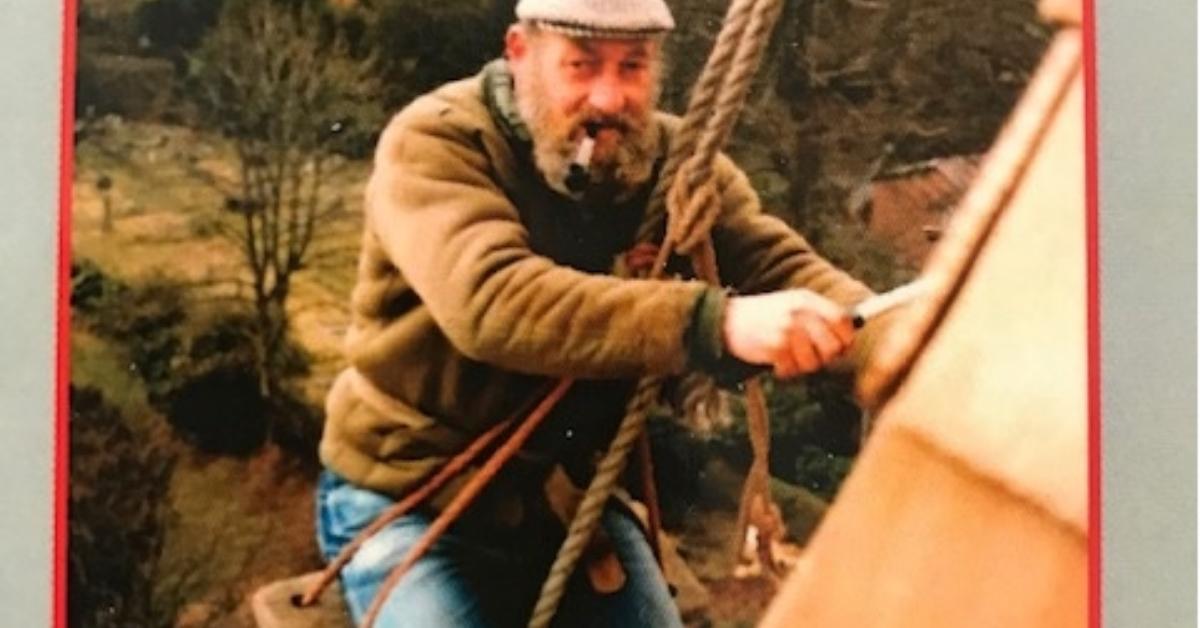

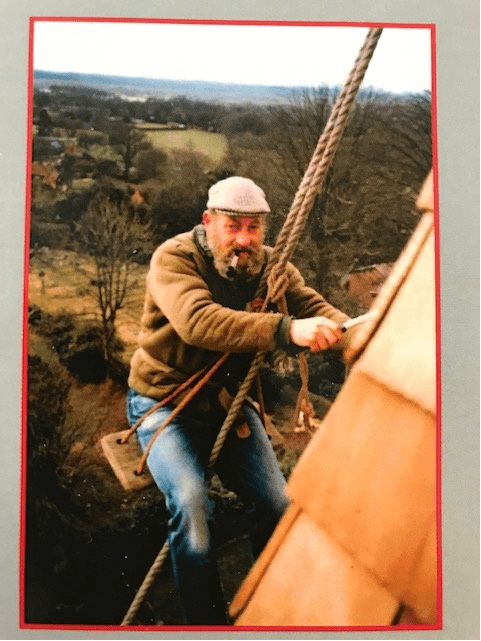

Peter’s life-long love of spires and steeples means they continue to be his workplace and his playground still. Having spent half of his life sitting on a bosun’s chair, dangling from churches while repairing and restoring them, Peter even has his own hand-cleft oak shake named after him!

What Is A Steeplejack?

Steeplejacking first came to be in the 16th century when travelling acrobats, with their poles, ropes and fearlessness around heights, made them ideal for this type of work. To advertise their bravery and boldness, they would swing off the spire for villagers and townsfolk to gasp at. In the process, many found there was more money in performing repairs than somersaults!

Since the days of the industrial revolution, steeplejacks have found themselves also climbing cooling towers, clock towers and industrial chimneys. They are a fearless bunch of highly skilled workers who are masters in lead, copper, iron and timber. Often using their own jargon for equipment and manoeuvres, they are experts at using ropes, ladders, levers, pullies and cantilevers.

Scaling tall buildings using ladders and ropes and using the Bosun Chair is where the real skill is seen. If this method can be used, rather than resorting to expensive scaffolding, steeplejacks can save ecclesiastical organisations a huge amount of money on church spire repairs.

The knowledge of safety that experienced steeplejacks developed from years of practice—everything from knot-tying to the specific use of ropes—has since transferred to the spheres of mountain-climbing and potholing.

The Career and Dangerous Deeds of Peter Harknett

According to Peter, the skills above also came in handy to keep a young lad tied to a spire all night! One summer evening, long before Health & Safety, some local lads in the pub had been bragging to Peter about how easy it all was: how to climb the ladders, swing on ropes and “touch the weather cockâ€. Soon enough, Peter ended up having to go up and rescue one of the heroes—but after making sure he was secure, left him up there all night until the following morning! By every good pub, there’s a good church, he suggests.

Following his national service, Peter joined Bertram Mills Circus as a rigger. After leaving to become self-employed, one of Peter’s first jobs was a school tower was in Surrey. This gothic tower needed re-slating, and he recalls working at the very top on a corner, bobbing in the wind when an unexpected gust caught him. Instead of halting his fall, the safety `fall rope’ had got in the way and wrapped around his leg, causing him to be knocked against the building and fall over eighteen feet, while the manilla rope rubbed across his shin and into the bone. His first aid kit, he says, was a bit of old rag and insulation tape! Patch-up completed, he then went straight back up the ladder and into the bosun chair.

The man’s plentiful stories are as awe-inducing now as they were back in his youth. Until recently, Peter used to cycle around the square steeple at the very top of Guilford Cathedral, with no safety nets. And at another point in his career, while he was working on a synagogue roof in Jerusalem, the army was so impressed with his acrobatics they asked him to fix a billboard onto the top of the 6m wall in the occupied zone. This Peter duly did, only for a scud missile to blast through the billboard into Israeli territory as he was working. He was deaf for two days!

Peter is still active to this day. He loves to drive and smoke his pipe, remaining a great raconteur with a wicked sense of humour. If you’re after a laugh, ask him about the stuffed crocodile, the jokes he played on unsuspecting passers-by, the naked lighthouse-keepers, or the occasional items of ladies’ underwear he has retrieved off weathervanes!

“Every day is a school day,†Peter often remarks, and it’s certainly true. We remain grateful for the vast knowledge he has been teaching others. It is a comfort and a joy to know he is passing on such a rich history of memorable conservation and restoration. You can buy his book, A Steeplejack’s View of Life, over on eBay.

UK Suppliers of Hand-Cleft Shakes and Shingles

Peter’s exploits have been many, but he is a leading authority on Oak shakes for spires. Oak and Larch shakes are a great roofing and cladding alternative, more long-term and durable than Cedar shingles.

Timber roofing tiles have been around since pre-Roman times and are still very common roofing practice in parts of Europe, such as Salzburg and parts of Bavaria. Oak shakes are cleft from a roundel cross-cut from the log—a disc, in effect—which is radially hand-cleft. They are all made parallel, tapering with the backs cleaned flat so they sit well on the spire, typically nailed to a sarking board in a three-layer tile construction. The huge advantages are weight and durability: if laid correctly, the oak is very durable and can last well over 80 years.

Peter used to cleft his own shakes from roundels we cut in our yard. However, through Peter’s introduction, we now work with a family firm Called Rapold GmbH and Co, based in Bad Reichenhall. Together, they designed a new style of shake and named it the Peter Harknett Oak Shake.

Particularly suited to ecclesiastical buildings such as church roofs and spires, these shakes are designed and manufactured by Rapold GmbH, our Bavarian shakes supplier. They are 300mm long and hand-split with a tapered parallel cut but approx 8/10mm thick, which certainly gives woodpeckers a headache! Through our work with Peter and Harold, we now distribute these hand-cleft oak shakes for all manner of church and building cladding.

Read more on the benefits of and differences between shakes and shingles.

W. L. West & Sons Ltd is a timber merchant and sawmill business with 150 years of experience. We provide a wide range of air-dried oak and kiln-dried oak timber products and supplies. We also build and install custom projects for our customers.

For more news, tips and updates, follow us on Facebook, Twitter, or Instagram.

For entirely finished products, timber supplies or woodworking tools, have a look at our Retail Shop (which is temporarily closed for lockdown but will re-open in due course).

Liked this article? More like this:

Hardwood Timber: Ash Wood Properties & Uses

Outdoor Timber Products & Solid Wood Garden Furniture by WL West

Timber & Wood Glossary Of Terms

Machined Timber Suppliers | Machined Timber Services | Wood Cut to Size UK